Renewable Energy

We are always motivating industries to decrease their ecological footprint and consider innovative approaches by providing advanced solutions. With our custom-made solutions, we want industries to adopt sustainable practices and minimize their negative impact on the environment.

ZEPHYR™

A high tech textile complex for the next generation of wind turbine blades

Conventional windmills have blades entirely made of composite materials. This makes them heavy, difficult to repair in case of damage, and impossible to recycle at the end of life. Together with ACT Blade, we developed Zephyr™, a textile laminate that is stretched over the lighter rib structure of the newly designed wind turbine blades.

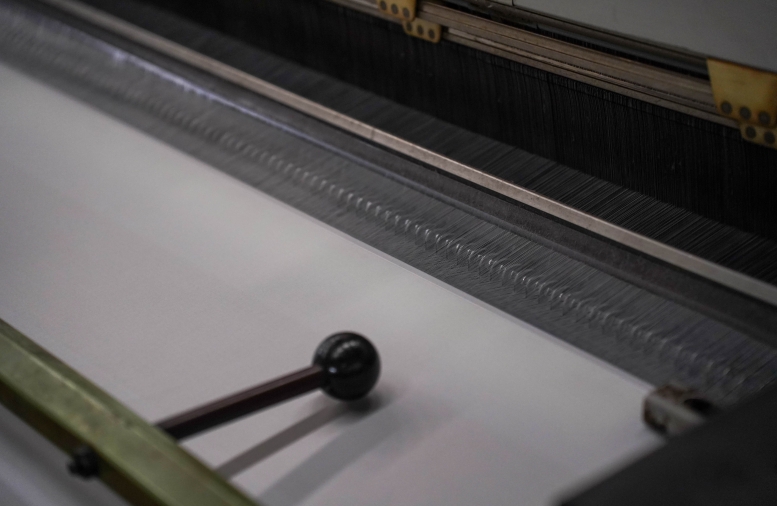

FABRIC

Zephyr™ is a laminate made of specially engineered yarns for strength and fire resistance and a customized protective membrane.

TESTING PROCESS

Zephyr™ conforms to 24 parameters and passed several tests such as rain erosion resistance, UV-resistance, tear- and tensile strength, lamination force, resistance to lightning strikes, weather resistance, etc.

CO-DEVELOPMENT

We co-developed Zephyr™ with ACT Blade, who use their technology to design the world’s most efficient wind turbine blade. Together, we’re on a mission to create the next generation of blades.

ZEPHYR™ CONTRIBUTES TO MORE SUSTAINABLE, DURABLE, AND ENERGY-EFFICIENT BLADES

LIGHTER BLADES

LONGER BLADES

MORE ENERGY GENERATED

REDUCTION IN THE LCOE